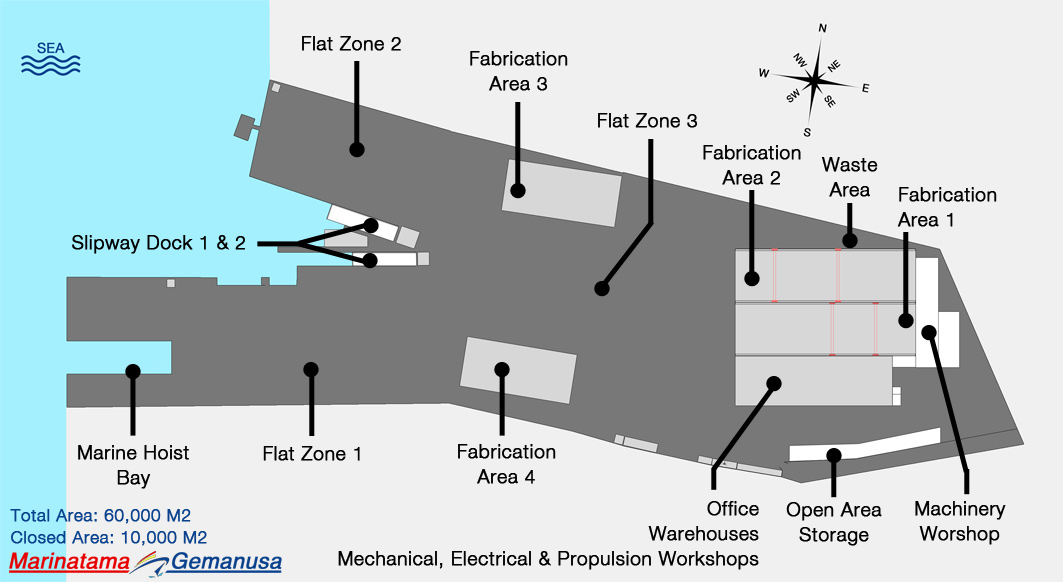

Facilities

Slipway dock with its capabilities in safely launching and retrieving vessels combined with our experienced docking team providing ideal docking option for short-term hull related inspection, maintenance and repair.

The marine inflatable airbags with size up to 1.8 m diameters, 14 m length, provide one of the most economical option for ship launching and hauling out.

| Docks | Dock 1 | Dock 2 |

| Type | Slipway Dock | Slipway Dock |

| Capacity | 120 Tons | 150 Tons |

| Length | 30 Metres | 45 Metres |

| Width | 7 Metres | 8.5 Metres |

Fabrication Workshops & Flat Zones

Four closed fabrication areas of total more than 8400 Sqm enable ship building, repair, blasting and painting processes to be carried out simultaneously regardless of the weather conditions. There are also 3 flat zones spreading over 21000 Sqm in the shipyard to accomodate every kind of shipbuilding and repair.

The largest fabrication areas are divided into 2 sections and equipped with cnc plasma cutting, bending, rolling machinery with up to 20 mm thickness. The overhead crane lifting capacity is max. 40 tons/total of 2 cranes for each section.

| Area Facilities | Size |

| Fabrication Workshop 1 | 96 M x 27 M x 24 M |

| Fabrication Workshop 2 | 96 M x 27 M x 24 M |

| Fabrication Workshop 3 | 60 M x 30 M x 15 M |

| Fabrication Workshop 4 | 60 M x 24 M x 12 M |

| Flat Zone 1 | 150 M x 70 M |

| Flat Zone 2 | 95 M x 50 M |

| Flat Zone 3 | 130 M x 50 M |

The electrical workshops have comprehensive facilities and experienced team for wide range of electrical panels work, wiring and installation for electronics and navigation instruments. The Shipyard also has dedicated teams to handle all kinds of air conditioner and alternator works.

The pipe workshop is focusing on steel, stainless steel and PVC pipes fabrication, outfitting and installation for water, fuel, drainer, low and high pressure hydraulic system.

The workshops have wide range of division to handle mechanical repair of auxiliary / propulsion engines, outboard motor, pumps, compressor and gears. Our experienced technicians can carry out engines top and general overhauling in our facilities.

The workshops include various machinery and tools, capable of fabricating, repairing and reconditioning facilities for propeller shaft and bracket, rudders, couplers and propellers with dedicated workers.

| Units | Quantity | Specification |

| Workshop Overhead Cranes | 4 | 2 Cranes/Workshop Max. Lifting 20 Tons (main) + 5 Tons (additional) each |

| Hand Torch Plasma Arc Cutting Machines | 2 | (1) Max. Cutting Thickness 51 MM, Max Gauging Rate 40 Kg/Hr (2) Max. Cutting Thickness 25 MM, Max Gauging Rate 8.8 Kg/Hr |

| Lathing Machine | 4 | (1) 3 Meters Length, 100 MM Diameter (2) 6 Meters Length, 250 MM Diameter (3) 3 Meters Length, 75 MM Diameter (4) 4 Meters Length, 180 MM Diameter |

| Portable Diesel Air Compressors | 3 | |

| Electric Air Compressors | 1 | |

| Forklifts | 2 | Max. Lifting 3 & 7 Tons |

| Excavators | 2 | Engine CAT & Cobelco |

| Crawler Crane | 1 | Max. Lifting 50 Tons |

| Buldozer | 1 | CAT D7 |

| Truck with Crane | 1 | Max. Lifting 3 Tons |

| Marine Inflatable Airbags | 16 | Diameter 1.0 - 1.8 Meters Length 12 - 14 Meters |